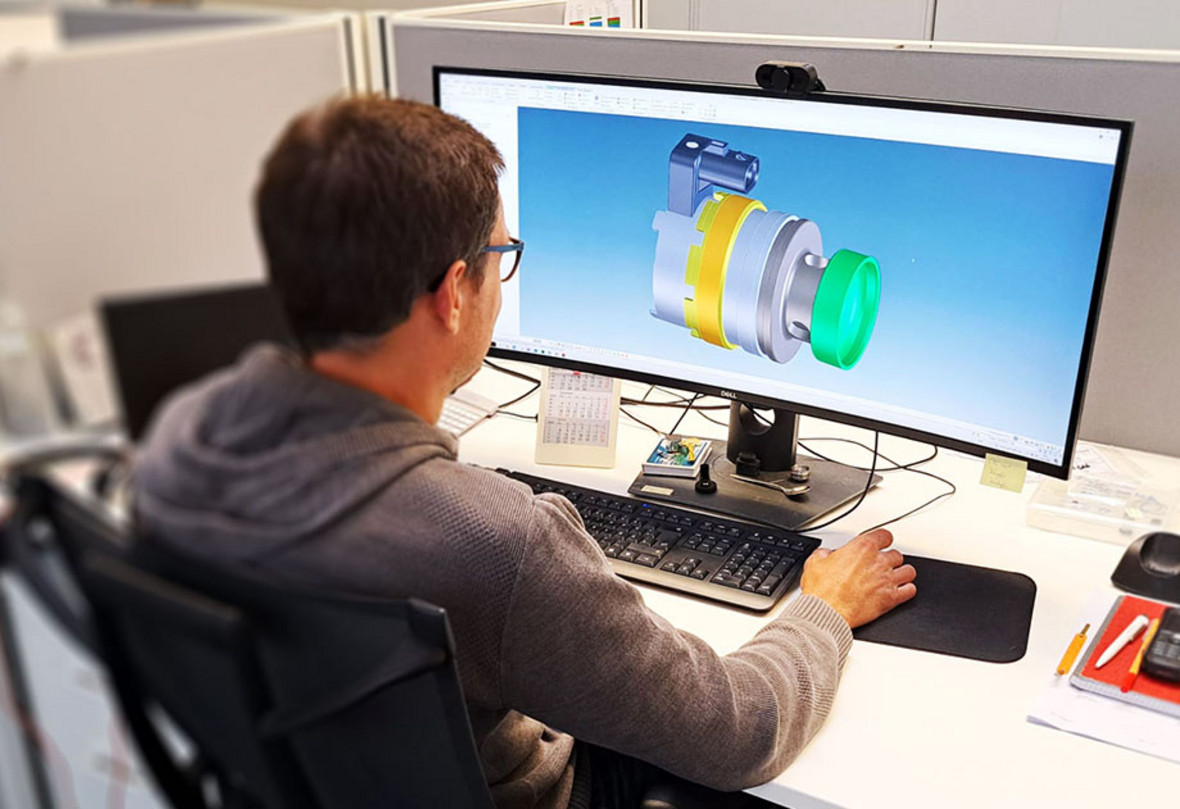

We have the right solution for your challenge. That's why we develop and manufacture customized solutions at a high technical level that are perfectly tailored to the needs and goals of our customers. With us, you don't get standard off-the-shelf products, but individual solutions that range from the idea to the product to series production.

Our core competence is to make individuality affordable. We focus on flexibility and innovation in order to transform concepts or ideas into products ready for the market and series production. Our motto "Break the Standards - Set New Ones" reflects our passion for pushing the boundaries of what is possible and constantly taking on new challenges.

If you are looking for tailor-made solutions and don't want to compromise, then you've come to the right place. We can help you turn your ideas into reality and meet your individual requirements. Let's set new standards together and revolutionize your industry.

Find out more about our range of services and our R&D disciplines.

Our focus is not on the development and manufacture of standard products, but on the realization of unique solutions that meet your specific requirements.

Together with you, we create the right product for effective and efficient use in your industry. In doing so, we focus precisely on the specific requirements of your application.

We offer

- Customized solutions

- Application-specific solutions

- New developments

- Product modifications

- Minor adaptations and modifications

- Special requests

- Ready for connection with electronics and software

(Plug & Play)

With us, you will find combined expertise in mechanical design, electronic development, software programming and all production-related processes under one roof!

This service includes the development and design of individual components, assemblies or complete systems according to customer requirements. This can include the integration of electronics and software to provide smarter functions and services, such as control and power electronics with corresponding software.

In addition, RAPA has extensive in-house laboratory, simulation and validation facilities, which are used for intensive testing and validation in the product development process and in the creation of prototypes.

By taking a holistic approach to development and production, we are aware of the particular importance of the interface between the two areas. This is the result of many years of engineering experience. Process consulting plays an important role in research & development when quality assurance, scheduling, interdisciplinary product development and costs have to be managed simultaneously.

At our state-of-the-art production sites in Germany, North America and Asia, we have a wide range of production lines that can be quickly and flexibly adapted to the respective requirements.

At our main site in Selb, series production takes place in seven modern production halls with a total area of an impressive 13,500 square meters. We offer: Small, medium and large series (from 1,000 units to millions of units)

State-of-the-art production technologies for maximum efficiency and quality

- Standardized machinery with the latest technology

- Highly automated production lines

- Use of robotics

- Component assembly at validated assembly workstations

- 100% EOL testing (end-of-line) for maximum quality control

The production of components and systems requires careful planning and implementation in order to guarantee a product of the highest quality and reliability. Many companies outsource this process to external service providers in order to save costs and keep capacities free. But RAPA sees things differently. As a technology partner for various markets, we rely on one hundred percent in-house development and production. From design to production, the entire process is in our own hands and under our control.

The advantages for the customer are obvious: quality, speed and time to market. The close cooperation between development and production ensures that the quality of the products is maintained at the highest level.

Our experienced team of engineers and technicians ensures that every process step is optimally coordinated and meets the highest quality standards.

Our outstanding flexibility enables us to produce customized components and respond individually to the desired quantities. Through customized planning in our own production facilities, we support you in your planning and offer you a clear advantage. At RAPA, individual quantities are the focus of your specific requirements. Whether a single piece or millions of pieces - we offer solutions for different needs. We understand that the automotive industry requires completely different quantities than medium-sized industrial customers in other sectors.

Rocco Kemnitz

Head of Pre-Development

"Pre-development is the foundation for ground-breaking innovations. Through our extensive research and development, we create the basis for pioneering technologies that revolutionize our industry. Through the targeted use of simulations, we can significantly shorten the product development process. This enables us to find the optimum solution for our customers faster and more efficiently, while at the same time strengthening our ability to innovate."

For us, everything revolves around progress and the development of groundbreaking ideas. For us, innovation is not just a word, but a way of life. We firmly believe that creative thinking and courageous action can constantly redefine the limits of what is possible.

Our team of innovative minds is constantly on the lookout for new solutions and revolutionary concepts. We are convinced that innovation is the key to mastering the challenges of our time and actively shaping the future.

With passion and expertise, we are committed to improving existing processes, researching new technologies and implementing unconventional ideas. In doing so, we never lose sight of our customers' needs and strive to offer them real added value with innovative products and services.

Let's push the boundaries of what is possible and shape the future together. Because for us, innovation is not an option - it is our DNA.

Research partners and academic partners

RAPA relies on cooperation with renowned universities, colleges and academic research and innovation centers for the continuous development and perfection of processes and procedures. Together, we carry out projects based on simulation and experimental studies to improve the quality and performance of our products and production stages.

Research projects are carried out to investigate new materials, manufacturing techniques or technologies that can be used in valves and fluid solutions. The aim is to find innovative solutions that improve the performance, reliability or efficiency of the products.