At RAPA, we understand the challenges that arise both in the classic world of purely mechanical products and in modern mechatronic systems. Our goal is to offer solutions that meet the specific requirements of your tasks - from individual products in small series to large series with quantities of 100,000 and more.

Our experienced team of experts combines comprehensive know-how in the fields of mechanics and mechatronics. We combine traditional engineering skills with state-of-the-art technology to develop innovative solutions that meet your requirements.

500+

Development projects. We have the experience! Put it to good use!

160

Patent applications. Active since the founding days, around 50 DPMA patent specifications.

150+

Engineers. Technicians, developers, specialists, physicists

Mechanical construction

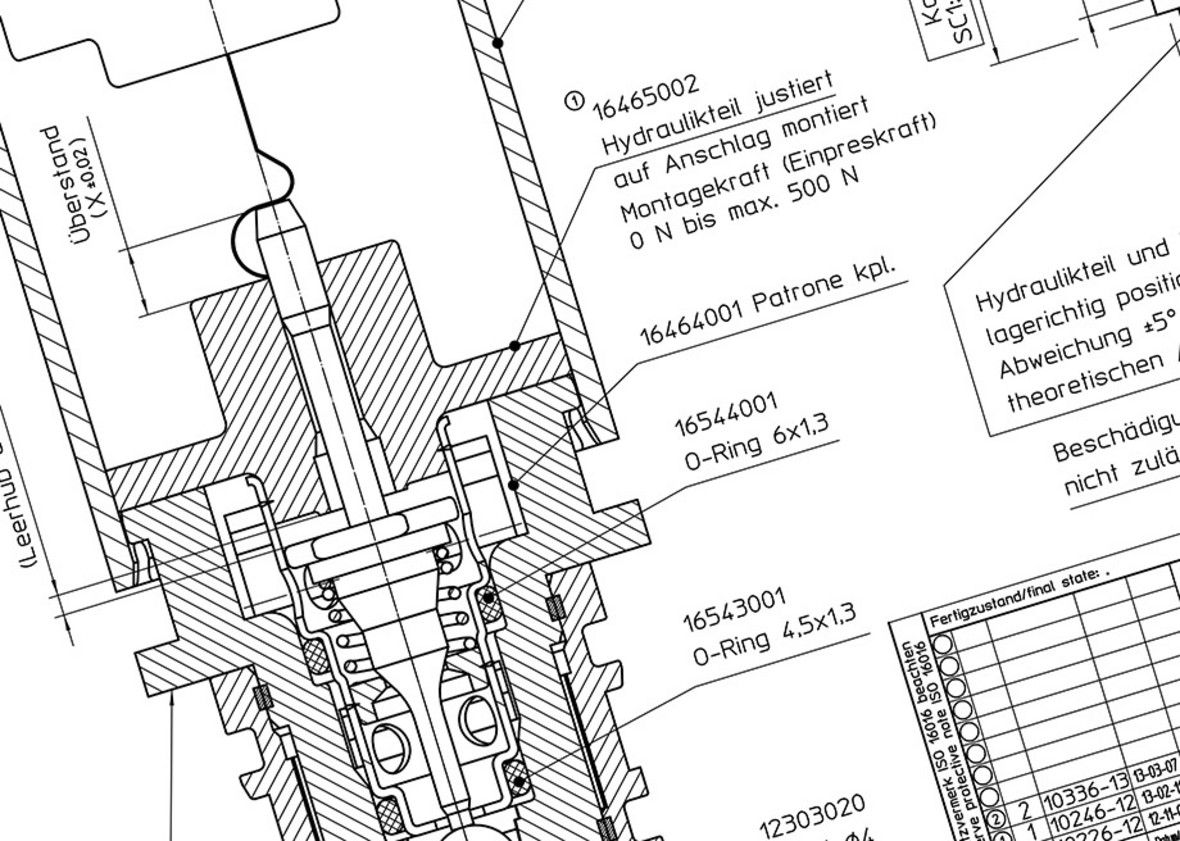

Mechanical and housing design & CAD

Our expertise in mechanical engineering and CAD design at RAPA enables us to develop innovative components that ensure a smooth flow in every application. We attach great importance to a production-optimized mechanical design that meets the requirements of different technologies and materials. Our experienced design engineers are passionate about the challenges of this task.

Our design teams provide advice and support in the selection of suitable components right from the early stages of product development. In doing so, we benefit from our wide range of processing machines and manufacturing processes, which enable us to combine even complex product designs into modern applications.

Specialist areas

Our area of expertise includes the design of hydraulic and pneumatic valves, solenoid valves, electromechanical assemblies and fluid-mechatronic systems. We also specialize in customer-specific special designs and function development. Our design engineers are also proficient in technical calculations to ensure optimum component performance and functionality.

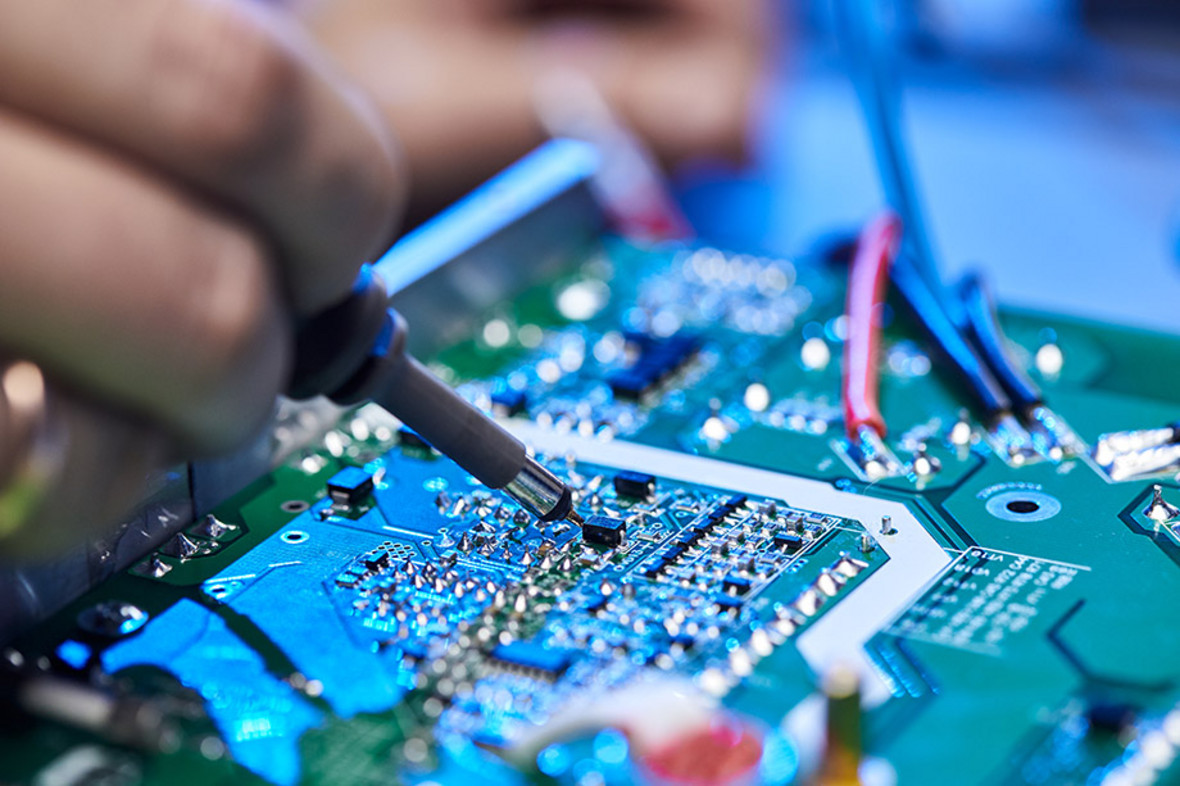

RAPA is continuously expanding its expertise in mechatronics and electronics to meet the growing trend towards sophisticated electronics and extensive software development. The company's Electronics Competence Center, established in 2019, contributes to the technological transformation by expanding the portfolio for complex product solutions and systems. RAPA ideally combines its many years of experience in valve technology, fluidics and mechatronics with its expertise in electric actuators and electronic control systems for valves and fluid-mechatronic systems to develop complete systems.

Smart services

In addition to product development, RAPA offers intelligent services, including specially developed electronics and corresponding control software. The result is a mechatronic modular system for intelligent valves that offers customers optimally coordinated integration solutions and strengthens system expertise in the areas of electric drives, actuators, power units, control and power electronics.

The advantages of RAPA solutions are manifold:

- Simple integration of the valves into the customer's overall system

- Optimum adjustment of the control to the valve to ensure the best possible operation

- Implementation of different operating modes depending on the application, e.g. dynamic switching or NVH-optimized switching

- Energy-optimized operation of the valves

- Integrated status monitoring and diagnostic functions

- Optional integrated sensors, such as pressure and/or temperature sensors

Prototyping, sample construction and testing

Prototype construction enables us to turn ideas and concepts into tangible models and subject them to thorough testing. This allows us to identify potential errors at an early stage, optimize functions and make design changes before the products go into series production.

Our prototyping department is equipped with state-of-the-art technologies and machines such as 3D printers, CNC machining centers and rapid prototyping processes. This enables RAPA to produce prototypes quickly and cost-effectively.

Once the prototypes have been built, they undergo extensive testing and evaluation. We carry out various tests to ensure the performance and reliability of our products. These include, for example, performance tests to check functionality under real-life conditions, leak tests to ensure that our products function reliably even under extreme conditions, and long-term tests to check longevity and durability.

In addition to the physical tests, we also use simulation methods to analyze the behavior of our products in various scenarios. Simulation-based testing allows us to create virtual prototypes and evaluate their performance before we produce physical prototypes. This enables us to reduce costly iteration loops and shorten development time.

Testing and simulation

Testing and simulation play a central role at RAPA to ensure the performance, safety and reliability of our products. With a wide range of tools and software solutions, we carry out extensive simulations and use specialized test equipment.

For our simulations, we use powerful software such as Ansys Workbench, Maxwell 2D and 3D, Simplorer, RMxprt, SimulationX, Matlab Simulink, Flow.EFD, Autodesk Moldflow and Altium Designer. We use these tools to analyze and optimize the performance of our products in various scenarios.

FEM simulation

Using the finite element method (FEM), we can analyze the structural integrity and strength of our components and assemblies. This allows us to predict how our products will behave under different loads and environmental conditions and make design improvements where necessary.

At RAPA, we have a clear priority to use testing and simulation as an essential part of our product development.

Validation involves the thorough assessment and confirmation of the conformity of our products or components with the specified requirements and standards. To ensure that our products meet the specified requirements, we use a variety of tests, inspections and documentation procedures. These validation methods ensure that the product meets customer requirements in terms of performance, safety, reliability and functionality.

In addition, we conduct inspections to verify the quality and integrity of our products. These inspections include visual checks, dimensional measurements and other specific procedures to ensure that the products meet the required standards.

In addition to the tests and inspections, documentation is an essential part of validation. By documenting all tests, results and test reports in detail, we ensure that all requirements are met and that complete traceability is guaranteed.

In-house central laboratory

Accredited test laboratory

Our in-house central laboratory is an accredited test laboratory in accordance with DIN EN ISO/IEC 17205 and enables us to carry out a wide range of tests and analyses to check the quality and performance of products. We offer a wide range of testing and measuring options in the fields of physics, chemistry, electronics, material analysis and environmental testing. We have a large test area where we can test the functionality and durability of products.

Equipment and services

- Extensive test field for functional and endurance testing

- Pneumatic and hydraulic parameter measurement (pressure, flow, leakage)

- Automated functional test benches

- E-motor measurement incl. high-voltage

- Electrical parameter measurement: current, voltage, resistance, inductance, PD

- Static material testing, force-displacement measurement (50kN, 1kN, 100N)

- Acoustics: airborne and structure-borne sound, class 1 acoustic chamber

- 15 climate, temperature and temperature shock chambers

- Salt spray chamber 2D and 3D coordinate measuring technology (tactile and optical)

- Technical cleanliness

- Materialography

If required, we work with a network of external partner laboratories to carry out additional specialized tests and analyses.

Project management

In a constantly evolving world, effective project management is essential to the successful implementation of engineering projects. At RAPA, we are experts in managing complex process and plant projects from start to finish.

Our project management team takes responsibility for the careful planning, coordination and monitoring of each project. We rely on clear target definitions, precise resource planning, well thought-out schedules and comprehensive risk assessment. By working closely with our clients and internal teams, we ensure that everyone involved is on the same page and achieves the project's objectives.

With our many years of experience and proven methods, we bring order to complex processes and create a solid foundation for success. Our focus is on understanding our clients' requirements and exceeding their expectations.

Quality management

Certified to the highest standards!

At RAPA, quality management is our top priority. We attach great importance to offering our customers products and services that meet the highest standards. With our many years of experience and in-depth knowledge of the industry, we have implemented an effective quality management system that ensures our products and processes meet the strictest quality standards.

To ensure that we are always up to date, we undergo regular internal and external audits. These audits allow us to continuously improve our procedures and processes and ensure that we meet the highest quality standards.

Logistics and warehouse

From development to production and delivery, we work with the utmost care to ensure smooth processes.

Our aim is to supply our customers cost-effectively and on time. To achieve this, we rely on customer-specific logistics concepts worldwide that are perfectly tailored to individual requirements. Our lean logistics processes are a key success factor. By using state-of-the-art technologies and intelligent resource management, we are able to keep delivery and call-off times flexible and short. This enables us to react quickly to changing customer requirements and guarantee maximum flexibility.